The transformation of a ship begins with the design of what will be done, starting with what the ship originally offers.

The design is therefore a crucial activity and requires a very high professionalism of technicians and architects, who have the difficult task of understanding the needs of the Owner in the best possible way and knowing how to insert them into the structure of the boat, avoiding as much as possible the distortion of the lines and of the forms; always and in any case respecting the expected quality, times and costs.

The design is therefore a crucial activity and requires a very high professionalism of technicians and architects, who have the difficult task of understanding the needs of the Owner in the best possible way and knowing how to insert them into the structure of the boat, avoiding as much as possible the distortion of the lines and of the forms; always and in any case respecting the expected quality, times and costs.

When the general layout is defined, the so-called “dirty” work phase begins, which concerns the overhaul of the hull and all the existing equipment and which will remain on board as they are reused.

In particular, attention is paid to adapting to the regulations of the Classification Bodies for the purposes of compartmentalization, safety, noise, etc.

The integrity of the hull is checked, the necessary sheet metal / planking portions are replaced, all the equipment on the hull is overhauled and the necessary new components are installed (bow / stern thrusters, stabilizers, etc.).

In particular, attention is paid to adapting to the regulations of the Classification Bodies for the purposes of compartmentalization, safety, noise, etc.

The integrity of the hull is checked, the necessary sheet metal / planking portions are replaced, all the equipment on the hull is overhauled and the necessary new components are installed (bow / stern thrusters, stabilizers, etc.).

Once the activities that require the boat to stay dry are completed, a first so-called technical launch is carried out and the works concerning the defined interior set-up and the correct arrangement of all the moving components (ballasts, water tanks) which involve variations begin. on the trim of the ship.

The transformation of the ship is completed with the general testing of all on-board equipment and delivery to the Shipowner.

The transformation of the ship is completed with the general testing of all on-board equipment and delivery to the Shipowner.

Here follows a selection of some relevant refit and transformation project performed across the years by RCN and the previous experiences of its founders.

Asso Project

Asso is a SAR vessel that served for the Finnish Navy from 1967 to 2007.

RCN (formerly Java Shipping) discovered the ship for a business customer who was looking for a multipurpose vessel to perform mid-range navigation, underwater works, surveys, coastal patrol, research and salvage.

After a initial survey and appraisal of the boat performed in Turku Finland, RCN managed the final negotiation of the price and the practices of sale and transfer of ownership. RCN also managed the disposal of the Finnish flag, the temporary registration with the Italian flag and the RINA certification procedures for the final registration in Italy.

Finally, RCN took care of planning, organizing and carrying out the transfer of Asso to Italy.

The navigation from Turku to Fiumicino was approximately 4,000 nautical miles across the Baltic Sea, the English Channel, the Atlantic Ocean, the Strait of Gibraltar and the Mediterranean, to destination.

Finally, RCN took care of planning, organizing and carrying out the transfer of Asso to Italy.

The navigation from Turku to Fiumicino was approximately 4,000 nautical miles across the Baltic Sea, the English Channel, the Atlantic Ocean, the Strait of Gibraltar and the Mediterranean, to destination.

D.P. Monitor project

The owner's request was for a vessel that would offer large outdoor and indoor spaces, with classic and rigorous fittings; in this section you can see how the transformation of the offshore tug Decio Primo promptly responded to the initial needs.

The research conduct led to the Decio Primo, a 30-meter offshore tugboat launched by the prestigious Benetti shipyard in Viareggio in 1953. Transferred from the port of Civitavecchia where it was located to the shipyards where the transformation works will subsequently be carried out, the D.P. Monitor was, in 1991, the first tugboat in Italy to be transformed into a luxury yacht. The project, which began in 1989, was carried out according to the highest quality standards by deeply revisiting the ship in every component, first bringing it back to its complete efficiency and then evolving it into the splendid yacht that is still admired today throughout the Mediterranean. The refitting works concerned the engine, the construction of a new electrical system that would allow the boat to use 4 alternative sources of energy .

The research conduct led to the Decio Primo, a 30-meter offshore tugboat launched by the prestigious Benetti shipyard in Viareggio in 1953. Transferred from the port of Civitavecchia where it was located to the shipyards where the transformation works will subsequently be carried out, the D.P. Monitor was, in 1991, the first tugboat in Italy to be transformed into a luxury yacht. The project, which began in 1989, was carried out according to the highest quality standards by deeply revisiting the ship in every component, first bringing it back to its complete efficiency and then evolving it into the splendid yacht that is still admired today throughout the Mediterranean. The refitting works concerned the engine, the construction of a new electrical system that would allow the boat to use 4 alternative sources of energy .

In the second phase, the interior was transformed into an amateur cabin, a VIP cabin and 3 double cabins, each with its own bathroom, 2 decks and a separate crew quarters. The Decio Primo is entirely completed and the D.P. Monitor has now seen the light.

The project ends with a final test of the ship, which includes a test of over 1,000 miles of sailing, and the subsequent handover of the ship to the new crew.

The project ends with a final test of the ship, which includes a test of over 1,000 miles of sailing, and the subsequent handover of the ship to the new crew.

As evidence of the goodness of the work carried out, we recall that from that summer of 1991 more than 20 years will pass before one of the subsequent owners feels the need to intervene on the ship for modernisation.

Don Giovanni project

In the "Don Giovanni" project, the Owners needed a boat with a small number of cabins, favoring the "all out", therefore the approach to the transformation minimized the structural impact of the ship as much as possible to exploit its better indoor and outdoor spaces available.

The Don Giovanni, launched in Kobe in Japan in 1964, has sailed for years between Singapore and Abidjan to transport the materials necessary for the construction of the port of the capital of the Ivory Coast.

Later, the Don Giovanni sailed under the English flag in the seas of northern Europe and then in the Mediterranean under the Italian flag, disarming in 1994 after 30 years of honorable service.

The Don Giovanni, launched in Kobe in Japan in 1964, has sailed for years between Singapore and Abidjan to transport the materials necessary for the construction of the port of the capital of the Ivory Coast.

Later, the Don Giovanni sailed under the English flag in the seas of northern Europe and then in the Mediterranean under the Italian flag, disarming in 1994 after 30 years of honorable service.

The Don Giovanni was selected and purchased in 2000, immediately starting its transformation through two distinct phases, as usual.

The first phase focused on the structural verification of the ship and all the technical aspects relating to engines, propulsion systems, rudders, hydraulic and electrical systems.

The second phase, on the other hand, started after the R.I.N.A. and after an exhaustive series of sea trials, it involved the final outfitting of the interiors.

It took about ten months of intense work to transform the interior of the Don Giovanni according to the wishes of the owners and make them as they are today. The leather of the sofas, the precious fabrics used for the coverings and furnishing accessories and the skill with which the teak surfaces are treated make the Don Giovanni interiors exclusive.

From the moment of delivery to the new owner, the Don Giovanni has sailed for over 30,000 miles always with the two magnificent original engines.

ETA of Lowestoft project

In the "ETA of Lowestoft" project, the Owners had similar needs to those that led to the choice of the "Don Giovanni", that is to limit the number of cabins to the minimum necessary for personal needs and maximize outdoor liveability.

RCN therefore had to identify the suitable means that would allow the project to be completed by making the most of the existing spaces and limiting the impact to the ship's structure.

After a long research that involved many shipyards in England, Norway, France and Spain, RCN chose to propose Eta of Lowestoft to Shipowners.

After a long research that involved many shipyards in England, Norway, France and Spain, RCN chose to propose Eta of Lowestoft to Shipowners.

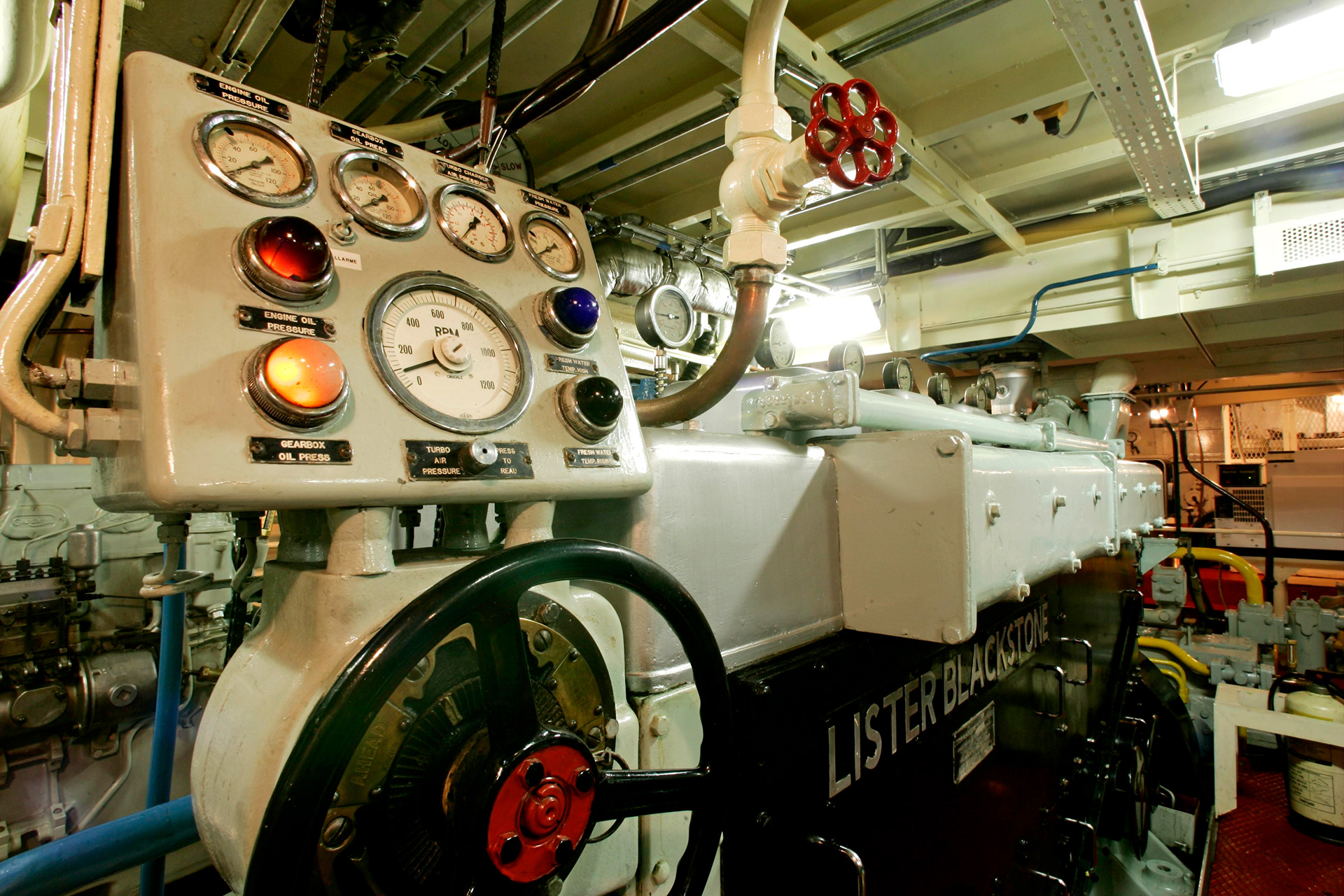

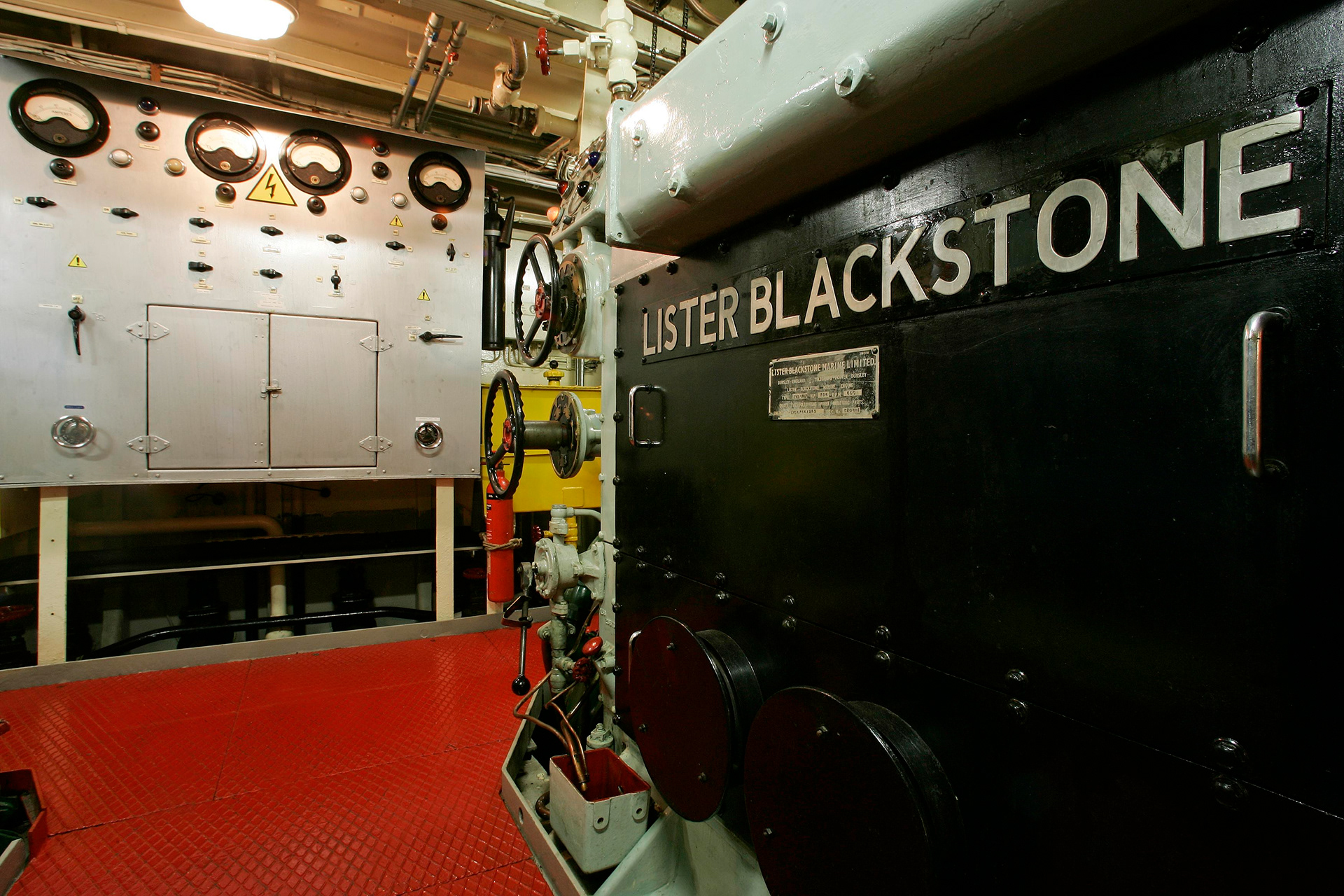

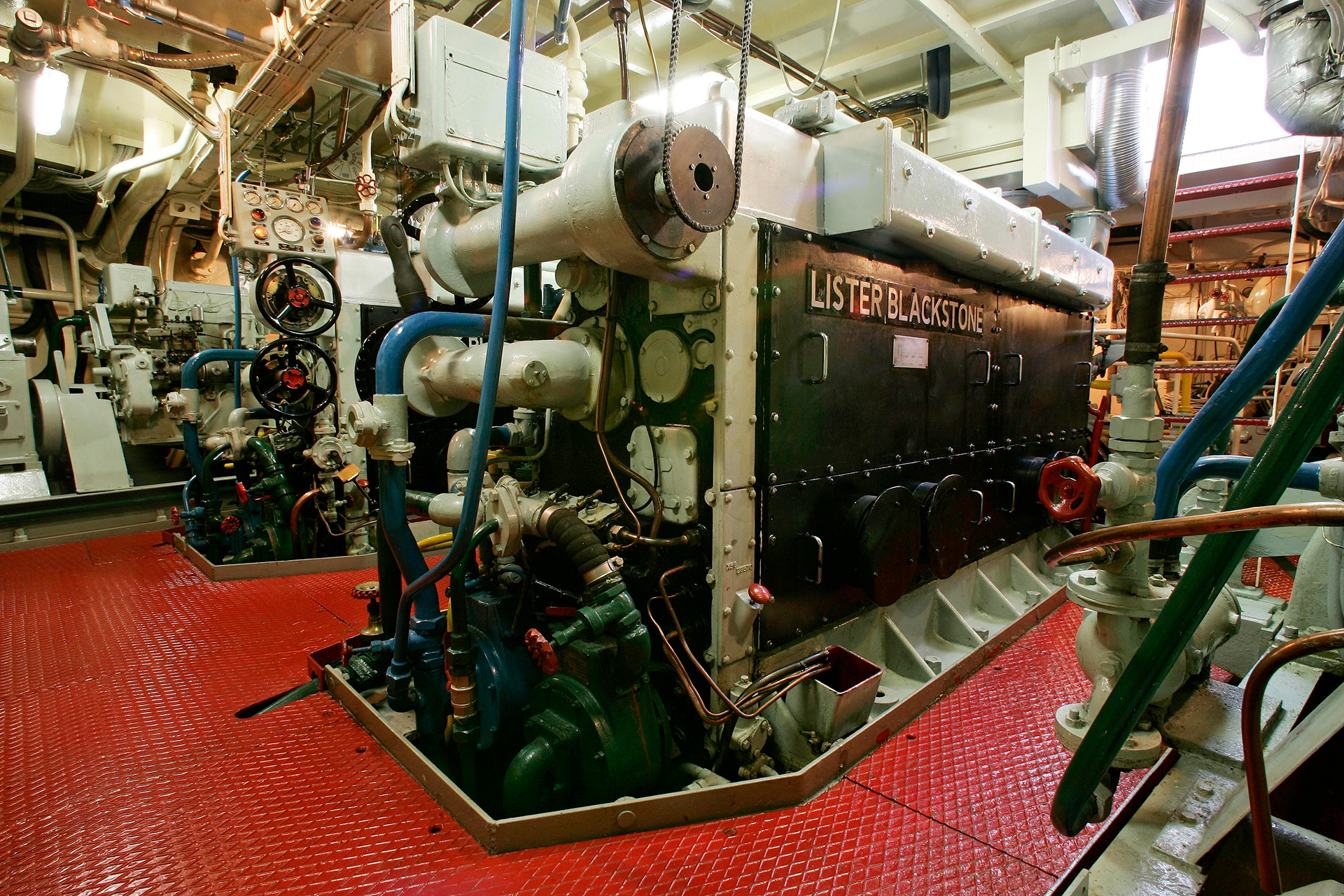

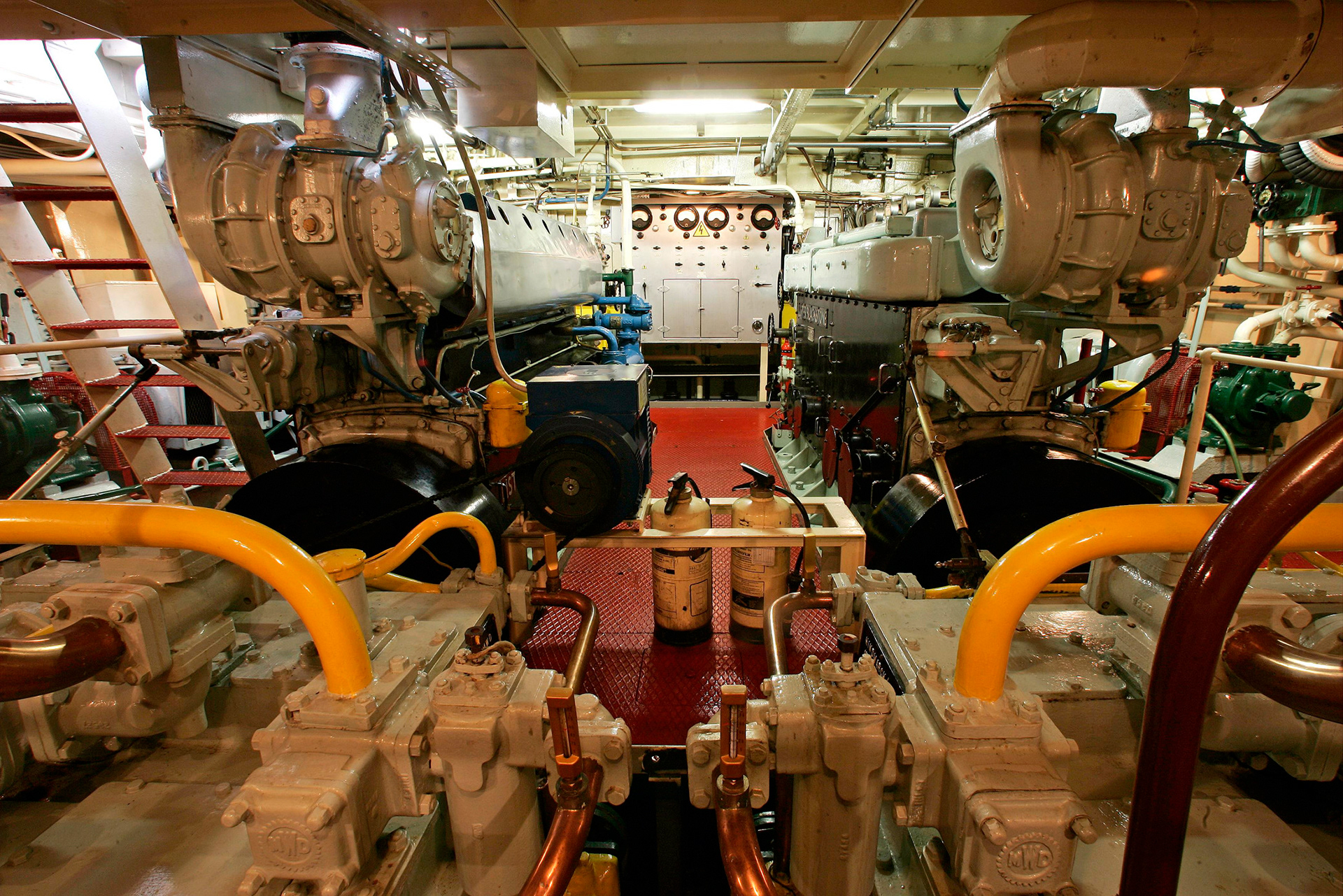

The Eta of Lowestoft was built in 1965 by Humber St Andrews Ltd, England. Its welded steel structure and propulsion with two engines and two propellers are just some of the features that made it an exceptional starting "platform". ideal for the completion of the renovation project.

Acquired the ship in 2003 we organised her transfer from Lowestoft to Fiumicino where the refitting works took place.

The transformation of ETA of Lowestoft took place in three different and complex phases:

In the first phase, the mechanics and the hull were completely overhauled with multiple repairs, sandblasting and maintenance of the engine room. New electrical systems, a new air conditioning system, new electronic navigation and communication systems, a new generator that integrated the two already present and overhauled were added.

In the second phase, the superstructures were replaced with a new deckhouse, new funnels and new equipment by removing the complex towing cable rewinding system and installing a new crane for handling the large tender supplied.

Finally, in the third phase, RCN took care of the transformation of the interiors with an amateur cabin on the upper deck and two double cabins for guests, each with its own bathroom; a saloon, a dining room, a kitchen and a totally autonomous crew quarters complete the interior layout. The outdoor spaces are characterized by a teak deck covering; a stern sunbathing area, an outdoor dining area and the construction of a second deck for housing the "toys" and the sunbathing area.

Precious materials and teak for the interior coverings make today the old tugboat a graceful and unpretentious luxury vessel.

Mastiff project

stands out from the other projects for an even different approach; in this case, in fact, the design of the interior layouts and superstructures was commissioned to a well-known architectural firm that created a highly innovative design that gives the ship an elegance that finds strength precisely in the contrast between the classic design of the hull and the deckhouse and of all the superstructures.

As in previous projects, RCN has taken care of the initial search for the ship, which ended with the identification of the ideal vessel in Mastiff.

The Mastiff was built in 1967 by Appledore Shipbuilders Ltd, in England, on request of the British Navy (Dog Class); Entirely in welded steel and with twin-engine / twin-propeller propulsion, the Mastiff remained in operation as a rescue and towing tug until 1999 with Lloyd Register class.

Since then the Mastiff was laid up but kept in perfect working order and its exceptional strength, its excellent condition and its great charm were decisive in the choice by RCN on behalf of the new Owners.

The Mastiff's transformation began even before he left Portsmouth.

The first dismantling of deck equipment was carried out in a local shipyard as well as maintenance activities in preparation for the transfer trip which ended in Fiumicino without particular difficulties.

The first dismantling of deck equipment was carried out in a local shipyard as well as maintenance activities in preparation for the transfer trip which ended in Fiumicino without particular difficulties.

Consequently, the first two phases of the project, research and identification of the ship and its transfer to Italy, were concluded, and the development of the design both in terms of systems and structural changes and in terms of the layout of the interiors continued.

During the construction phase of the new systems and the revision of the existing systems, the need to pass the difficult test of Class Certification was constantly kept in mind. Therefore, the utmost care has been paid to the efficiency of the engine and steering systems as well as the levels of

safety both on the compliance of the electrical system and on the fire protection requirements required for the high standards required by RINA regulations

safety both on the compliance of the electrical system and on the fire protection requirements required for the high standards required by RINA regulations

Our efforts have been crowned with full success with the achievement of the Class Certificate for Pleasure Ships obtained with the maximum score 100 A1-1.

Paolucci project

best represents RCN's ability to manage a high-level restoration project.

A very prestigious fast Motor Yacht built by the Picchiotti shipyard in Viareggio, entirely made of wood, originally armed as a representative yacht for the Presidency of the Italian Republic, and today restored by our company with "uncompromising" quality levels due to the ship's lineage.

It was an exciting challenge and a very difficult test, since the transformation involved practically the reconstruction of all the interiors, the replacement of all systems including propulsion and steering systems as well as the refurbishment of the main decks and the fliyng bridge.

The most difficult task was certainly to maintain the original unrepeatable elegance with the inclusion of absolutely modern technical and architectural details.

Great and rare example of collaboration between Owner, technicians and Architects, all leaning towards a common result.

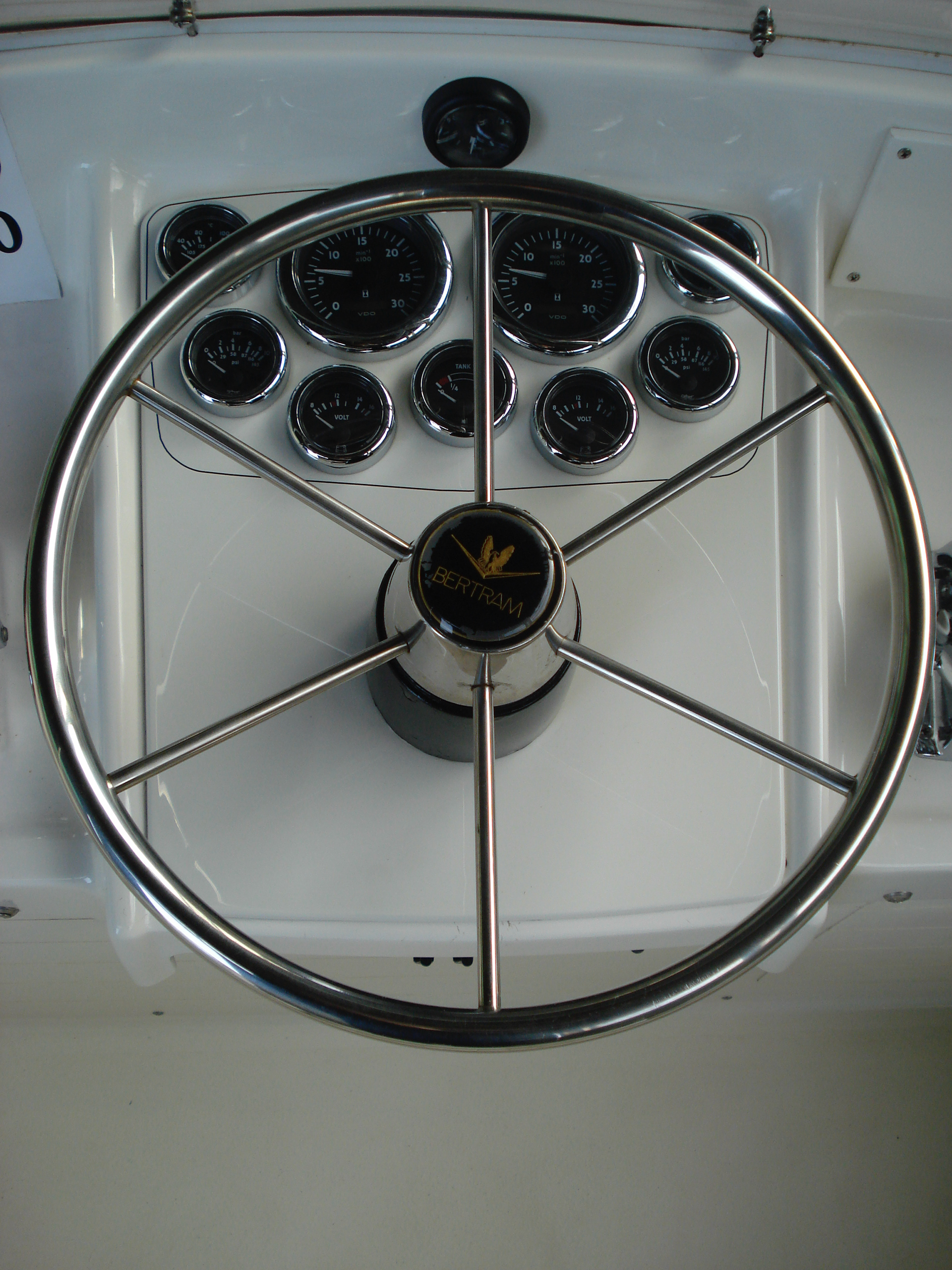

Bertram 31 Sport Fisherman project

This project has allowed RCN to deploy all its skills, from the search for the right boat, to the negotiation for the purchase, the handling of customs clearance and import procedures, the organization of transport, the construction site of the works, the repowering. , the complete refit, the advertising and the sale of the boat.

It all begins with the investment request of a customer who wants to market a legendary Bertram 31-foot Sport Fisherman in Italy, after having re-powered it with modern diesel engines while maintaining its originality at the highest possible level.

Our representatives then went to Florida in search of the most suitable boat and after having negotiated the purchase, they organized its transport by ship to Italy. Once the customs clearance and import procedures in Italy were completed, RCN used its technical skills to identify the most powerful diesel engine to be loaded. The choice was to mount two 370HP Cummins each.

In the meantime, every single component of the boat has been dismantled and overhauled or replaced if necessary.

New interior, new electrical system, new original steel finishes, new exterior and interior paint, new upholstery.

New interior, new electrical system, new original steel finishes, new exterior and interior paint, new upholstery.

At the end of the works the result is exceptional.

RCN then organized the exhibition of the boat at the BigBlue Boat Show in Rome where a buyer was quickly found and therefore the adventure ended with great satisfaction for RCN, investor and end customer.

A win-win-win project.

Grand Banks 36 classic project

In this case, the refit project was organised, promoted and produced directly by RCN, with its own funds.

The goal was to find a GB 36 in fair condition and carry out a complete restoration to bring the boat to new condition.

The boat was identified in Tuscany, after a careful search, and was transferred by sailing at the RCN shipyards in Fiumicino.

The goal was to find a GB 36 in fair condition and carry out a complete restoration to bring the boat to new condition.

The boat was identified in Tuscany, after a careful search, and was transferred by sailing at the RCN shipyards in Fiumicino.

The wooden boat was immediately brought to virgin wood and treated with traditional methods of protection with red lead and numerous successive layers of primers and enamels suitable for the type of boat.

The main engines and the generating set have been completely overhauled, all the interiors disassembled, sanded, copal painted and all the internal and external upholstery replaced.

A great deal of work was carried out on the main deck deck, all the old teak slats were removed, as well as the underlying marine plywood, the rotten beams were replaced and the still good ones were properly treated, then a new deck was rebuilt with bottom in multilayer marine plywood and Bruma teak slats longer than 6 meters.

The result is simply spectacular.

The result is simply spectacular.

After a summer season spent sailing around the Mediterranean in order to advertise the boat, a new owner bought it and still enjoys its use today.